Manufacturing Quality Standards

Quality Control for Plastic Injection Molding

Our quality inspection process ensures that only the highest quality plastic products are delivered to our customers. We understand there are a wide range of industry standards, which is why we design to meet or exceed standards as needed by our customers.

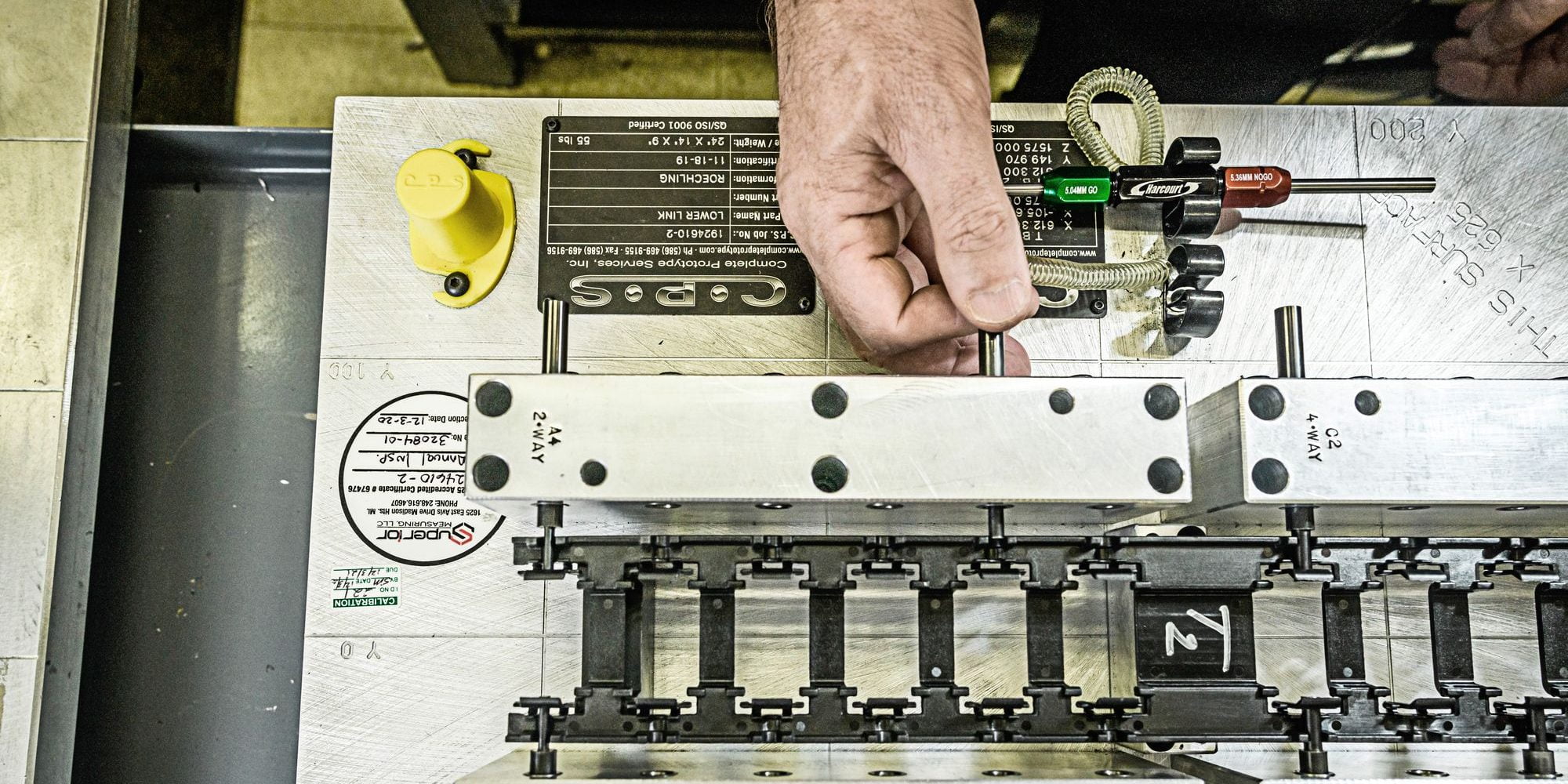

ISO Certification for Injection Molding Quality Management

Our company has earned the Quality Management System for Injection Molding Thermoforms qualification that complies with: ISO 9001:2015 Certification

Our Quality Assurance Process

Raw Material Inspection

All raw materials are verified for conformance upon receipt.

Visual Inspection

Parts are initially inspected directly out of molding machine. Quality Assurance technicians are trained to identify and rectify the following defects:

- Sink marks

- Short shots

- Burn marks

- Flash marks

Quality Station Inspection

Parts at the quality station are inspected for more detailed specifications like measurements or failure tests.

Final Part Inspection

Finished parts undergo one final inspection in our staging area ensure consistency across production shifts.